After final engineering is completed, manufacturing and fabrication of the membrane and structural steel begins. During the fabrication phase, prestress PTFE or PVC fabric membrane is cut and welded to create final panel sizes to be installed in the field. Once the manufacturing of the membrane and steel members are finished, packaging of the materials are carefully handled for shipping and unpacking at the job site.

Operating from a 47,300 square foot manufacturing facility with over 85 years of experience, there are virtually no limitations to the size and complexity of tensile structures we can build. Eide Industries is a Los Angeles Certified Fabricator (#FB01716 Type 1) with the ability to construct nearly any conceivable tensioned fabric structure.

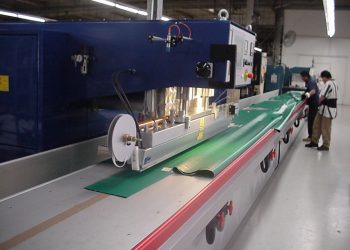

- Two 35-foot long RF (Radio Frequency) Heat Sealing Machines to weld PVC (Polyvinyl Chloride) and other high-frequency textile fabrics.

- Frame welding of carbon steel, aluminum, and stainless steel.

- Large format rolled ink, vinyl adhesive, eradication, cut and radio frequency sealed graphics, cold and heat transfers and digital applications.

- High-temperature PTFE (Polytetrafluoroethylene) heat sealing machine to weld fabric membranes.

- Industrial sewn membrane covers with HDPE (High-Density PolyEthylene) mesh or solid Acrylic fabrics.

- Custom full-size fabric pattern plotting, cutting, scanning and digitizing services for engineered precision fittings.